History takes time: Crafting the Speed Six Continuation Series

History takes time: Crafting the Speed Six Continuation Series

- First customer Speed Six Continuation Series car build underway

- Faithful continuation of the Speed Six, the most successful Bentley race car in history, with two Le Mans wins

- Highly successful test programme for Speed Six Car Zero prototype

- Two original Speed Sixes, including ‘Old Number 3’ works racer, used as templates to verify dimensions, materials and components

- Every car handcrafted from scratch using period-correct tools, fixings and techniques – over a process of 10 months from start to finish

- Team consists of Mulliner Classic in-house technicians and specialist British suppliers

- 12 customer cars all pre-sold

- Each customer offered a personal fitting for their car, with choice of period correct exterior and interior finishes

(Crewe, 20 March 2024) The first customer Bentley Speed Six in 93 years is now taking shape in the workshops of Mulliner, Bentley’s in-house bespoke and coachbuilding division. Its creation unites the skills of British engineering and restoration specialists with those of Mulliner’s team of master technicians. Twelve Continuation Series Speed Sixes will be built, using period-correct materials and techniques to ensure total fidelity to W.O. Bentley’s original design.

The Bentley Speed Six Continuation Series follows the successful completion of twelve Bentley 4½ Litre Supercharged ‘Blower’ Continuation models, the world’s first pre-war continuation series. All twelve Speed Six Continuation Series have been pre-sold, and customers will be able to specify their vehicles from a choice of period-correct finishes and materials. The build of each car will take a total of ten months from start to finish.

The first prototype of the Continuation Series – known as Car Zero – has had a busy schedule over the last six month, completing a series of engineering development work. 40 hours of engine testing has been followed by 10,000 km of durability running on a variety of surfaces, and the car recently completed top speed testing, achieving 112 mph – exactly as the originals would have.

Keeping craft traditions alive

The rough and ready setting of Bentley’s original Cricklewood factory is far removed from the meticulous order of Mulliner workshops. Yet each Continuation Series Speed Six will be built using tools, materials and techniques that would have been familiar to W.O. Bentley and his team in the 1920s. To achieve this, Mulliner has called on a network of specialist British engineering and restoration experts.

To create the chassis of the Speed Six, Portobello Engineering in Matlock follow the original engineering drawings faithfully. Their first step was to create over 20 tonnes of tooling to press the 5mm thick S355J2 steel that would become the Speed Six’s chassis legs and crossmembers, a process of research and development that alone took over six months. Once pressed into shape, the chassis legs and crossmembers are trimmed, checked, and deburred, before finally being assembled using the BSF (non-metric) bolts that would have been used in Bentley’s Cricklewood workshops.

Meanwhile, over in Ludlow, the ash frame for the Speed Six body is hand-crafted using traditional coachbuilding tools and techniques by specialists Lomax Coachbuilders. Once the frame is united with the Speed Six chassis at the Mulliner workshops, the team there will clad it in around 25 meters of Rexine, a highly specialised period-correct fabric, to create the Speed Six’s Weymann-style open tourer bodywork.

The father and son team at Vintage Headlamp Restoration International Ltd in Sheffield are celebrated for their ability to create vintage-design headlamps from original specifications. They are crafting exact recreations of the distinctive Speed Six headlamps that played such an important role in lighting the works cars to victory through the night at Le Mans in 1929 and 1930.

The Vintage Car Radiator Company, based at Bicester Heritage, are experts in classic car radiators and components, and the only company in the world to manufacture all 28 different types of pre-war radiator construction. They contribute the Speed Six’s radiator core, the mirror-polished, solid nickel silver radiator shell, and the hand-beaten fuel tank in steel and copper.

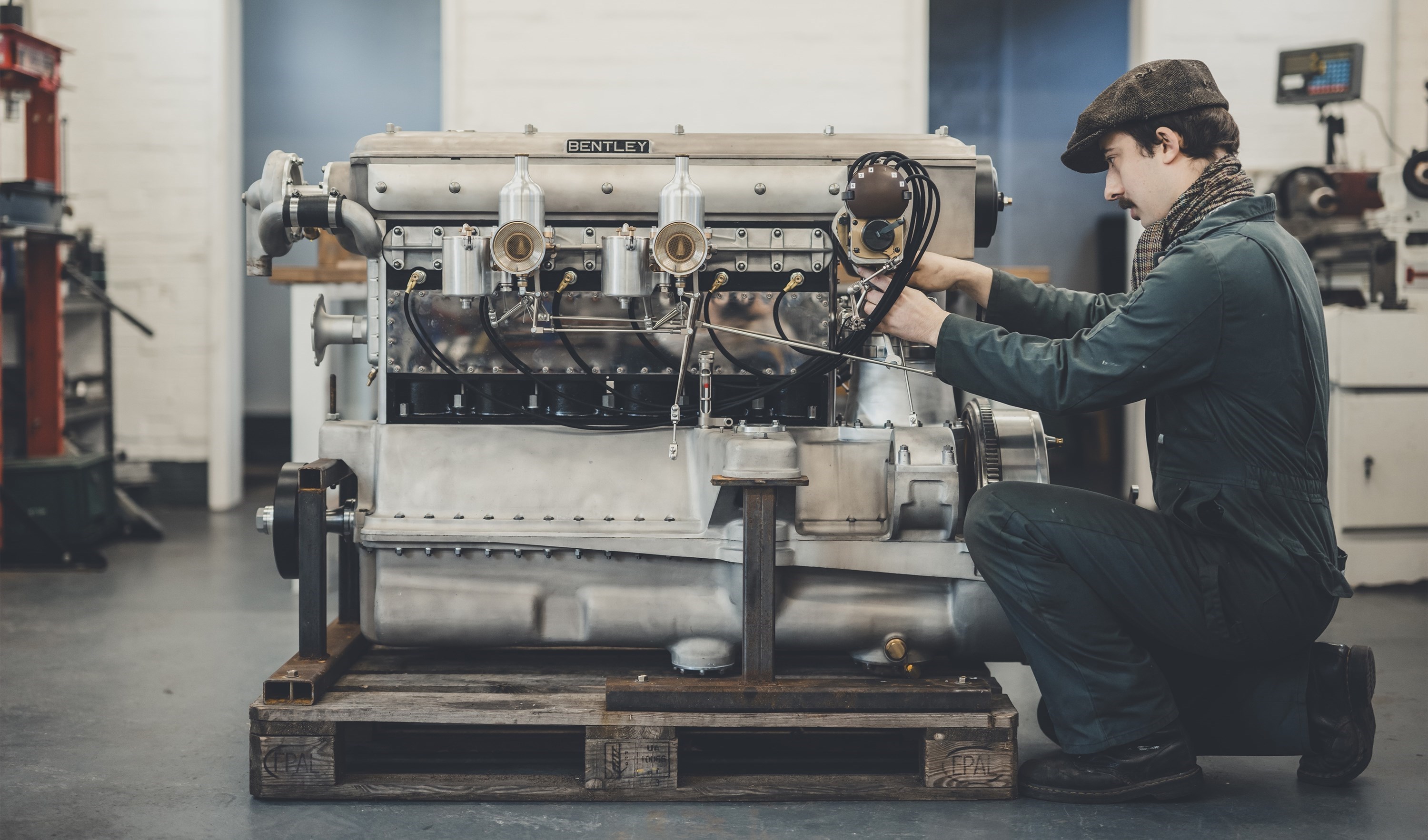

Also based at Bicester Heritage are Kingsbury Racing Shop Limited, specialists in the restoration, preparation, and servicing of vintage Bentleys. Working in conjunction with Tom Dark Engineering, original drawings were converted into 3D models, before more than 600 individual parts including a new engine block casting were fabricated for the new 6½ Litre race specification engine, which in period developed 200 bhp. The design of the Speed Six’s 6597cc engine was highly advanced for its time, featuring four valves and two spark plugs per cylinder, and an eight-bearing crankshaft. Initial dyno testing has shown the Continuation Series engines to develop 205 bhp – more power would be attainable with modern materials, but the intent of the Continuation Series is to create a Speed Six exactly as it would have looked and performed in 1929.

The Speed Six master template

The Continuation Series Speed Six takes two original Speed Sixes as its template: the company’s own Speed Six, GU409, and ‘Old Number 3’, a works Speed Six driven in the 1930 Le Mans 24 Hour race by Sammy Davis and Clive Dunfee. The latter was generously loaned by its owner and gave the Mulliner team invaluable data on dimensions, materials, and components.

The Mulliner Classic team is also indebted to the W.O. Bentley Memorial Foundation, which has provided 80% of the original drawings and notes used by the team. The Continuation cars include modifications that were made by the Bentley works team to improve reliability and performance in the 1929 and 1930 Le Mans 24 Hour races.

The legendary Speed Six, on track and road

The Speed Six was introduced in 1928 as a more sporting version of the Bentley 6½ Litre. The engine was modified to liberate more power, with twin SU carburettors, a higher compression ratio and a high-performance camshaft. A contemporary road test in The Morning Post concluded, “I consider this car to be one of the most remarkable engineering achievements of the century, the balance of speed, silence and flexibility having been maintained in a unique manner.”

182 Speed Six models were built between 1928 and 1930. Two wins at the Le Mans 24 Hour race, in 1929 and 1930, cemented the Speed Six’s pre-eminent place in Bentley racing history.

Another Speed Six made the headlines in March 1930 when Bentley Chairman Woolf Barnato raced the Blue Train from Cannes to Calais in his H.J. Mulliner-bodied saloon. Driving non-stop through the night, three-time Le Mans winner Barnato and co-driver Dale Bourne covered over 570 miles, averaging 43.43 mph on the rough and dusty roads of pre-war France. They even had time to catch the ferry and drive to London, arriving at the Conservative Club in St. James’ Street at 3.20pm, four minutes before the Blue Train arrived in Calais. The French authorities later fined millionaire Barnato £160 for racing on public roads, a small price to pay for a feat that has gone down in Bentley history.

- ENDS -